If you intend to do any sort of DIY work or are new to woodworking, you’ll need to choose the perfect drill driver in order to get the job done right. With so many options available, it can be hard to pick the right one for your needs. This is where our guide comes in handy! In this DIY 101 blog post, we’ll walk you through the essential factors that make a good drill driver and share useful tips to help you select the best one for your project. From power and speed to ergonomics and versatility, we’ll cover all the key aspects you need to consider before making a purchase. So, let’s dive in and find out how to choose the perfect drill driver for your specific requirements!

Table of Contents

- What is a Drill Driver?

- Types of Drill Drivers

- Factors to Consider When Choosing a Drill Driver

- Final words (Choose the Perfect Drill Driver) …

What is a Drill Driver?

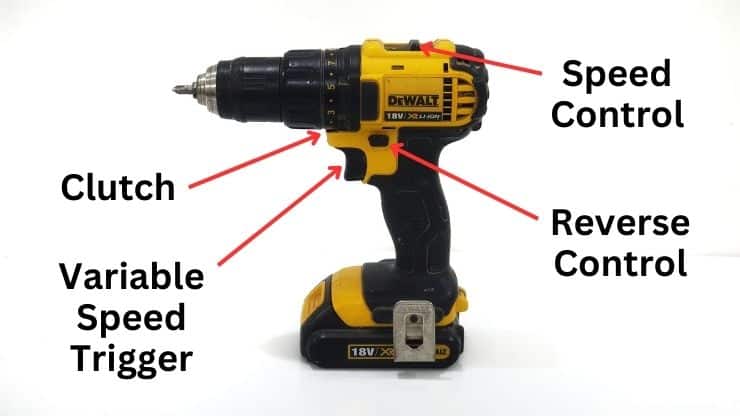

When you want to pick the perfect drill driver, especially if you’re new to woodworking or DIY projects, it’s important to think about its features. Most drill drivers are powered by batteries and have a special part called a clutch. The clutch stops the drill from spinning when it meets a certain level of resistance, which helps prevent over-tightening and stripping of screws. This is great because it keeps your project materials and screws from getting damaged while you work.

In addition to the clutch, most drill drivers also come with a reverse control, which allows you to change the direction of the drill’s rotation. This is particularly useful when you need to remove screws or bolts that have been driven in too far or are otherwise stuck in place.

Another feature that’s common in drill drivers is a speed selector, which lets you choose the speed at which the drill rotates. This is important because different materials require different speeds in order to be drilled effectively. For example, if you’re drilling through metal, you’ll want to use a slower speed to prevent the drill bit from overheating and becoming damaged.

Finally, most drill drivers come equipped with a variable speed trigger. This allows you to control the speed of the drill with your finger, giving you maximum control over the tool. By lightly pressing the trigger, you can start the drill slowly and gradually increase the speed until you reach the desired level.

Overall, the combination of these features makes drill drivers incredibly versatile and easy to use. To choose the perfect drill driver, you must consider your needs as a professional woodworker or a DIY enthusiast. A good drill driver is an essential tool that will help you get the job done quickly, efficiently, and safely, so it’s crucial to find the right one for your specific requirements.

To find out more about these controls, see the following articles on this blog:

- What Is A Drill Driver?

- What Is A Drill Driver Clutch?

- What Is A Drill Driver Reverse Control?

- What Is A Drill Driver Speed Selector?

- What Is A Drill Driver Variable Speed Trigger?

Types of Drill Drivers

When it comes to choosing the perfect drill driver for your project, it’s important to consider the type of drill that will work best for your needs. Here are the three main types of drill drivers to consider:

Corded Drill Drivers

Corded drill drivers are known for their reliable and sustained power. They are ideal for heavy-duty tasks that require constant power output, such as drilling through thick materials or driving long screws. Corded drill drivers are also typically more powerful than their cordless counterparts, making them a better choice for jobs that require high torque. However, corded drill drivers are limited by their cords, which can restrict mobility and create tripping hazards. They can also be challenging to store due to their cords.

Cordless Drill Drivers

Cordless drill drivers are highly portable and offer greater flexibility and maneuverability than corded drill drivers. Recent advancements in battery technology have enabled cordless drill drivers to match the power of corded drill drivers for an ever-expanding variety of tasks. When looking to choose the perfect drill driver, it’s important to consider the type of drill and its features. Cordless drill drivers are typically easier to store than corded ones and often come with individual storage containers to house the tool and its accompanying batteries. However, the battery life of cordless tools can be a limitation, and their performance can suffer as the power gets drained. Additionally, the attached battery adds extra weight and bulk, which can cause strain and fatigue when using the tool for extended periods of time. Therefore, it’s essential to balance the advantages and disadvantages of cordless drill drivers and choose the perfect drill driver that best suits your needs.

Hammer Drill Drivers

Hammer drill drivers are similar to cordless and corded models, but they come with additional features that make them suitable for heavy-duty tasks like drilling through concrete and masonry. They have a hammering mechanism that helps to break up tough materials, making it easier to drill through them.

One thing to keep in mind is that hammer drill drivers can be heavier and more difficult to use than other types of drill drivers, so they may not be suitable for everyone.

Similar Tools That Are Not Drill Drivers

Impact Drivers – An impact driver and a drill driver with a hammering function are similar in that both provide a percussive force. However, they differ in the direction of the force they apply.

A hammer drill applies the percussive force in the direction of the bit, which helps to break up tough materials like concrete or brick. This is achieved by the drill driver’s hammering action, which delivers a rapid succession of blows to the material being drilled.

An impact driver, on the other hand, applies the percussive force in the direction of the turning motion. This works to deliver a high amount of rotational force to the fastener being driven, making it easier to drive screws and bolts into tough materials like wood or metal.

SDS Drills – An SDS (Slotted Drive System) drill is a type of power drill that is designed for heavy-duty applications, such as drilling into concrete, masonry, or stone. It features a unique chuck system that is different from the standard chuck found in drill drivers and impact drivers. The SDS chuck is designed to accept SDS drill bits, which are specifically designed for use with the SDS drill.

When looking to choose the perfect drill driver, it’s important to understand the differences between various types of drills. The primary difference between an SDS drill and a drill driver lies in its design and intended use. While drill drivers are designed for general-purpose drilling and driving applications, SDS drills are specifically designed for heavy-duty applications that require high levels of power. They feature a hammering action that is similar to that of a hammer drill. This hammering action is achieved by a piston mechanism within the tool that delivers a powerful hammer blow to the drill bit as it rotates. Therefore, it’s crucial to consider the nature of your tasks and choose the perfect drill driver that will offer the power and versatility you need to complete your projects efficiently and effectively.

In addition, SDS drills have a chuck system that ensures the drill bit remains securely in place even when used on tough materials. This is important to prevent slippage and loosening during drilling operations.

In summary, an SDS drill is a specialized power tool that is designed for heavy-duty drilling applications. It is different from a drill driver in terms of its chuck system, hammering action, and power.

Factors to Consider When Choosing a Drill Driver

Selecting the right drill driver can make all the difference in your DIY project. With so many options available, it’s important to consider the following factors to make an informed decision:

#1. Chuck Size – The chuck size determines the size of the bits the drill can accommodate. Most drill drivers have chucks that range from 3/8 to 1/2 inches. Consider the size of the bits you’ll be using and choose a chuck with the right size.

#2. Torque – Torque is the measure of a drill driver’s twisting force. It’s an essential factor to consider when selecting a tool as it determines the drill’s ability to drive screws and drill through tough materials. A higher torque is ideal for heavy-duty tasks, while a lower torque is suitable for lighter tasks.

#3. Speed Settings – A drill driver’s speed settings determine how fast the tool rotates. Some models have a single speed, while others have multiple speed settings. Consider the type of project you’ll be working on and choose a drill driver with speed settings that can accommodate your needs.

#4. Power Source – Drill drivers can be corded or cordless. Corded drill drivers draw power from a wall outlet, making them suitable for heavy-duty tasks; cordless ones rely on rechargeable batteries and are therefore more portable but not as powerful. Consider the type of project you’ll be working on and choose a power source that can accommodate your needs.

#5. Brand and Price – Choose a reputable brand when purchasing a drill driver. They are more likely to offer quality products and good customer support. However, high-quality tools come with a higher price tag. Consider your budget and balance cost with quality.

#6. Ergonomics – Comfort is key when using a drill driver, especially if you’ll be using it for extended periods. Look for a tool with comfortable handles, a good grip, and minimal vibration. You don’t want a tool that will cause hand fatigue or discomfort.

#7. Versatility – When choosing a drill driver, it’s important to consider how versatile it is. While many drill drivers come with basic features like variable speed triggers and keyless chucks, some models have more advanced features that can make them more versatile. Look for features such as a brushless motor, which provides more power and longer battery life. A drill driver with a compact and lightweight design can also be more versatile as it can be used in tight spaces or for extended periods without causing fatigue. A versatile drill driver will help you tackle a wider range of tasks and make your work more efficient.

#7. Durability – The durability of a drill driver is another important factor to consider. Look for models made of durable materials that can withstand wear and tear. A tool with a sturdy construction will last longer and save you money in the long run.

#8. Warranty – A good warranty is a sign of a quality product. It gives you peace of mind and protects your investment. When selecting a drill driver, it’s important to carefully examine and compare warranty terms and coverage across various brands and models, as this can prove to be a deciding factor when making your choice.

In conclusion, choosing the right drill driver for your DIY project requires careful consideration of the above factors. Take your time to research and select a tool that meets your needs, budget, and preferences. With the right drill driver, your DIY project will be a success!

Final words (Choose the Perfect Drill Driver) …

In conclusion, we hope that this DIY 101 guide has provided you with the essential knowledge and insights needed to confidently choose the perfect drill driver for your project. By taking into account factors like power, speed, ergonomics, and versatility, and by understanding the differences between the various types of drill drivers, you can make an informed decision that best suits your specific needs and preferences.

As you embark on your woodworking or DIY journey, it is essential to choose the perfect drill driver. Remember that patience, research, and comparison of different models are key to finding the ideal tool that will not only make your tasks more manageable but also enhance the overall quality of your work. With the right drill driver, you’ll be well-equipped to tackle your projects with ease, efficiency, and satisfaction, ultimately transforming your creative ideas into reality. Therefore, take the time to evaluate your needs and choose the perfect drill driver that will help you achieve your desired results.

Did you enjoy reading this? If so, you might like to visit my Pinterest profile. It contains pins about DIY & Crafts, Woodworking, Tools, Projects, Hardware, and related topics.