When sitting in the garage one day, I wondered how long to let the wood glue dry before sanding.

This is a very important matter: You don’t want to ruin your project and waste all of your efforts because you started sanding too soon! Will you ruin your project if you start early? Does this make any difference? How does this time depend on the type of glue, and other factors? The thought of this situation disturbed me, so I did a little research:

Most Wood glues only need clamps on them for about 30 minutes to 1 hour. After that point, you can do some light sanding, as long as you do not subject the joints to stress. The glue has not cured fully at that point, so the joint does not have full strength. It will reach full strength in about 24 hours.

However, there are many factors to consider such as the type of glue, temperature, and humidity. This post will look into some of these factors and also show how they can affect your project.

Note: This post may contain affiliate links. If you purchase a product through an affiliate link, I’ll earn a commission, at no cost to you. To find out more, see my full disclosure.

Wood Glue Drying Time

What do we mean when we talk about wood glue drying time? Actually, it is made up of several distinct times:

Open Assembly Time

When you apply glue to the surface of wood, is there a time limit before the boards have to be put together? Yes, this is known as the open assembly time. If your project is very complicated and there are many wood surfaces to be glued, you want to make sure that you can put all the boards together before the open assembly time is over.

This term seems to be used in many ways by people and there is more than one definition. I am going by the definitions of assembly time put forth here.

Closed Assembly Time

Okay, you stuck the boards together. However, you see that things are not right. As an example, the bookcase you’re putting together is not square. You need to reposition some of the glued pieces to get things back in shape. How much time do you have to do this? This is known as the closed assembly time.

Some wood glues give you a little more time to do this than others. You may need that extra time to make small adjustments. In that case, glue with a higher closed assembly time would be a good idea.

Total Assembly Time

This is the sum of the open assembly time and the closed assembly time. It represents the time from the start of the wood gluing to the time when the wood is positioned correctly and you are ready to put the clamps on.

Clamping Time

You need to have the wood pieces in clamps so that they are immobile and cannot change position. Then, they need to be in the clamps for a certain minimum amount of time. This allows the wood glue to cure partially. After this point, the clamps can be removed safely. However, the joint will not have full strength yet.

You can go ahead and sand the wood at this time. However, you must be careful not to apply stress to the joint.

When the glue has cured completely, the joint has full-strength. You can subject it to stress. In fact, the glued joint is probably stronger than the wood itself! If you try snapping the glued joint, the wood will break. However, the glued joint will remain intact.

Why Sand The Wood Glue?

A natural question at this point is: Why sand the wood glue? After all, the glued pieces are all square. They form a flat surface. Well, here’s a reason:

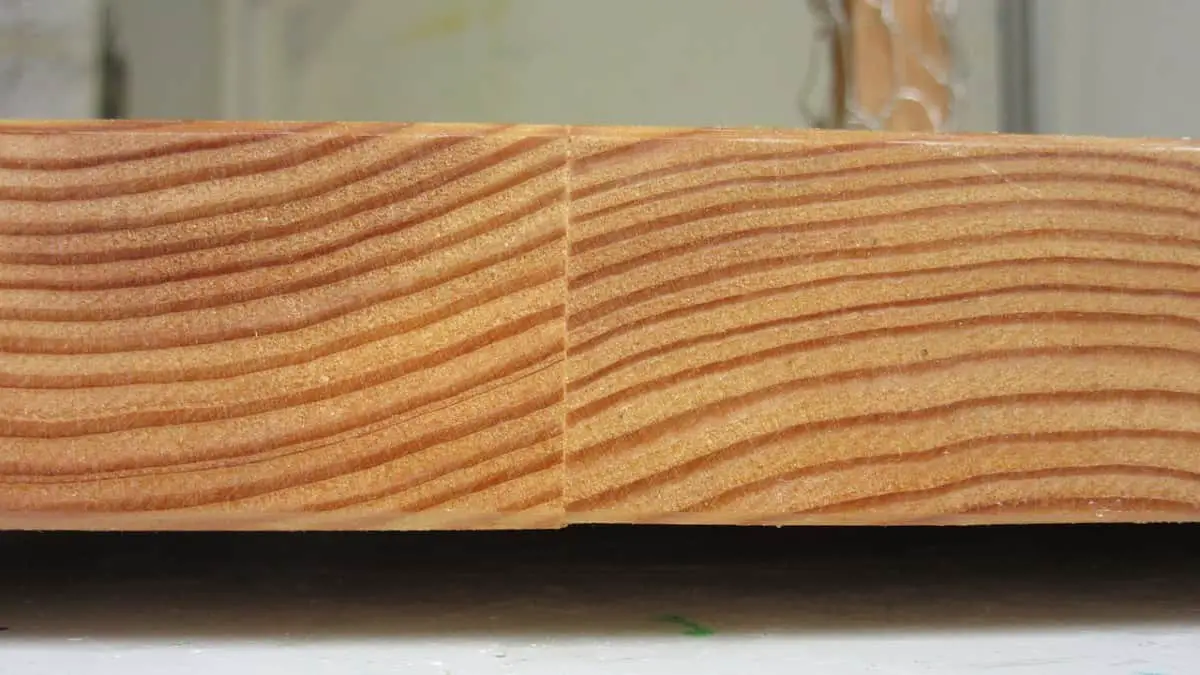

When you tightened the clamps, the glue was pushed out of the joint seams. You probably washed off the excess glue with water. This water caused the wood to swell near the seams. The wood expands and forms “peaks”.

It seems as if you should sand these “peaks” down to make the wood surface flat again. However, if you do this, the “peaks” will turn into “valleys”.

Why is this? Well, the wet wood will eventually dry. When this happens, the swelling will be reduced. If you sand the wet wood, you will remove some material near the seams. So, the dried wood will return to a lower position and form the “valleys”. The moral of this story is: Avoid sanding while the wood is moist to keep the surface nice and flat. I have written an article about sanding wood.

How Long To Let Wood Glue Dry Before Sanding: Types of Wood Glue

As we mentioned above, different types of glue have different wood glue drying times. What are these types?

PVA (Polyvinyl Acetate) Wood Glue

These are some of the most common wood glues. The joints they make are extremely strong. Also, they clean up with water. So, if you get any on your hands you can just use a wet rag to get it off. Also, when you clamp the wood together and a gob of glue comes out of the joint seam, you can use a wet rag to remove it.

Polyurethane Glue

You normally need to moisten one of the wooden pieces. This type of glue cures by using moisture from the pieces and from the atmosphere itself. Also, the total assembly time can be 15 minutes or so. Nevertheless, it can be harder to work with this type of glue since it does not clean up with water. Also, it can discolor your skin if you get it on it. Many people wear gloves when using this type of glue.

How Long To Let Wood Glue Dry Before Sanding Summary: Types of Wood Glue

We have not covered all the types of wood glue. There are many others such as epoxy glues, hide glues, and CA or cyanoacrylate glues. Each has its own positive as well as negative factors. This table lists several popular glues:

| Titebond Original type = PVA open assembly time = 4-6 min. total assembly time = 10-15 min. clamping time = 30 min. to 1 hr. full cure = 24 hrs. |

| Titebond II Premium type = PVA open assembly time = 3-5 min. total assembly time = 10-15 min. clamping time = 30 min. to 1 hr. full cure = 24 hrs. |

| Titebond III Ultimate type = PVA open assembly time = 8-10 min. total assembly time = 20-25 min. clamping time = 30 min. to 1 hr. full cure = 24 hrs. |

| Gorilla Glue type = Polyurethane open assembly time = 1-5 min. total assembly time = 6-15 min. clamping time = 1-2 hrs. full cure = 24 hrs. |

It can be seen that Titebond III Ultimate PVA glue gives more total assembly time than the other glues. Also, note that Titebond II Premium has less open assembly time than Titebond original. In addition, polyurethane Gorilla Glue has a similar open time. However, it is harder to work with. Nevertheless, it makes a very solid joint and is extremely strong.

How Long To let Wood Glue Dry Before Sanding Summary: How To Choose The Right Glue

There are many types of woodworking glue. They take different times to dry. This You Tube video shows how to pick the right glue for your woodworking job.

How Long Do You Leave Clamps On?

You probably want to sand the wood after you remove it from the clamps, in order to remove any glue residue. When should this be done? There are many opinions regarding the best time to remove clamps on a wooden project. Here is advice from two renowned woodworkers:

…it certainly does not hurt to leave the wood in clamps until you are ready to machine it, or until the clamps get in your way or are needed elsewhere…

– Michael Dresdner, Woodworker’s Journal

… Some glue makers strive to provide a product with a long open time and a short closed clamping time. For my money, a job that relies on glue to hold it together is worth more time, so I leave stuff in clamps a couple of hours…Titebond says you can take the clamps off, but you don’t have to…”

– Ian Kirby, Woodworker’s Journal

How Long To Let Wood Glue Dry Before Sanding: Removing Excess Glue

When you tighten the gluing clamps, excess glue will squish out of the joint seams. If you’re using PVA glue, you can wipe it with a wet rag. This will remove most of the excess. However, you might not get all the glue residue. How do you remove it?

You can remove this by sanding the board. Here is a link to an article I wrote about sanding.

You need to do this after the wood is completely dry. The reasons for this are described in the “Why Sand The Wood Glue” section above.

Another option is to use a plane, wood chisel, or wood scraper. However, you must make sure you do not gouge the wood and ruin the surface.

The situation is even more difficult with polyurethane glues such as Gorilla Glue. When the glue has dried there is really no way to remove it short of some sort of a mechanical process. So, you could scrape it with a knife or chisel. If it gets on the skin, the manufacturer recommends that you wait several days for natural exfoliation to take place. You can try to speed that process up with an abrasive compound such as sugar or pumice.

IRWIN QUICK-GRIP Clamps, One-Handed, Mini Bar, 6-Inch, 4-Pack

You can never have enough gluing clamps. Having enough clamps makes your job easier, and more satisfying. Also, it can actually improve the quality of the result! If you use enough clamps to totally, absolutely, lock the pieces in place during drying, the bonds can be better and stronger.

These clamps come in a 4 pack and are easy to use. They are designed for one-handed operation. This is in contrast to clamps that must be screwed to close.

How Long Does It Take Wood Glue To Dry?

As we saw in the section above, this depends on many factors including the following:

- The type of wood glue – As we can see from the above table, the Full Cure time for PVA wood glues is comparable to the Full Cure time for polyurethane glues. However, we see that the Clamping Time for polyurethane glues is greater. This might make a difference if you need to take off the clamps in a hurry to use for some other work.

- The temperature – Higher temperature speeds up the drying time.

- The humidity – Lower humidity speeds drying time with PVA glues. Polyurethane glues can tolerate much more moisture since moisture helps that type of glue cure.

So, now you know how long to let wood glue dry before sanding. As you can see, it depends on many factors. Also, there is no requirement that you remove clamps at the minimum possible time. Instead, it is perfectly fine to keep the wood clamped until Full Cure, as long as you don’t need the clamps for something else.

Check out my boards on Pinterest. If you enjoyed reading the article, please share.

Good post. I definitely love this site. Keep it up!

By the way, Gorilla Wood Glue is a PVA glue, not a polyurethane glue.

Just thought you’d like to know.

Sorry! I was really referring to the Original Gorilla Glue with a polyurethane formula. Yes, they make several other products:

Gorilla Wood Glue, Gorilla Epoxy Glue, Clear Glue, White Glue, Super Glue, and so on …

Thanks for the comment. Have a nice day!

In my experience when you use a water-based/PVA glue such as TiteBond, Elmer’s, etc waiting 2-3 days – or even longer if you’re not in a hurry – means that when you sand, your joints are much less likely to move afterwards and ruin the snug fits you spent all that time on.

The difference between waiting and not waiting is the difference between a happy outcome and a “Damn, I should’ve waited!” outcome.

It depends on the wood to some extent but remember that water swells wood and most wood glue is water based. Also glues can take quite a while to stabilise and can remain soft within the joint, depending on the wood, the humidity, the type of joint, the joint stress, etc.

So, if you can, give your joint(s) a few days to stabilise. That’s what I do with TiteBond II anyway.

Thank you so much for your comment and sharing your experience with us! You bring up a great point that waiting for the glue to dry completely is crucial to ensure a strong and stable joint. It’s interesting to learn that even after the glue appears to be dry, it can still take some time to fully stabilize and harden within the joint. I completely agree that taking the time to wait a few days before sanding is well worth it to avoid any potential movement or damage to the joint. Thanks again for your comment and adding to the conversation.