In the recent few years, there has been a significant increase in the number of people who are indulged in home renovation projects. Such massive interest has generated new avenues for the development of assembling tools and equipment. But such tools, although very useful, require a lot of knowledge from the user to be used efficiently. One such tool is the jigsaw blade. The key question that arises here is “what is meant by the TPI of jigsaw blades?” It is simply explained in this article:

TPI is an acronym for teeth per inch. This is a measurement of the number of teeth on a blade at one inch in from the edge. The higher the TPI, the finer the finish on a cut. The most common TPI ratings for jigsaw blades are from 6 to 24. A 60 TPI blade has 6 teeth in one inch, while a 24 TPI blade has 24 teeth in one inch.

The sections below will go into more detail:

A closer look at TPI

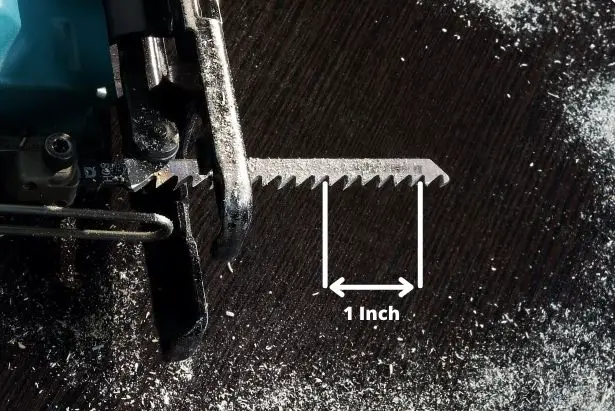

We know that TPI stands for “teeth per inch”. However, how do we measure that on a blade? To answer that, we need to mention what a “gullet” is. Essentially, the gullet is the curved part of the blade between two blade teeth.

Start at one gullet and then travel down the blade 1 inch to another gullet. If you then count the number of teeth between those two gullets, you will come up with the TPI for that blade.

The acronym TPI is also commonly used to represent “Threads Per Inch”. This is an unintended double meaning for the acronym TPI. Threads Per inch refers to bolts and screws. It has nothing to do with Jigsaw blades!

Is more TPI better?

TPI affects how much material is removed with each cut. As TPI decreases, the teeth grow in size. So, the teeth tear out more material as they cut. As a result, the cut can be rougher. However, it takes less time and effort to slice through the material.

When the TPI increases, the teeth are finer, and less is cut out as the blade moves up and down. This results in a smoother cut. Also, having more teeth is appropriate when cutting denser materials like metal.

To really answer the question “Is more TPI better”, we need to know what the operator is trying to accomplish. If he/she is only trying to make a cut through wood, a blade with a lower TPI would be fine and might actually make cutting easier. However, the cut would be rough.

Rough cuts might be acceptable for construction work. In that case, the operator is mainly interested in slicing through wood pieces quickly and accurately. When working with 2x4s, there’s no need for a smooth cut.

However, things are different when you’re making fine furniture: Smooth cuts are critical. This is even more important if the surface will be visible once the project is complete.

Furniture pieces often need to be stained or coated with a finish. Rough, splintered edges will absorb too much stain. This produces an unsightly mess!

Sometimes, it’s possible to avoid this situation by sanding the edges down. However, this is not always possible with large splinters in the wood. Occasionally, you can make a repair with wood filler. However, it’s best to avoid the problem in the first place.

Which TPI value should you use?

Tooth per inch (TPI) is a term used to describe the number of teeth a jigsaw blade has in one inch of its cutting edge. The higher the TPI value, the finer and smoother the cut will be. In general, high TPI blades are better for cutting fine details and intricate cuts than low TPI blades, which leave rougher edges and require more sanding.

There is no single, best TPI value. As we have mentioned, it depends on the particular situation. The table below lists typical values for common materials:

| Material | TPI |

|---|---|

| Wood | 6-24 |

| Plywood | 20 |

| Plastic | 8-14 |

| Acrylic | 10 |

| PVC | 10 |

Note that the TPIs for wood, plastic, and metal are expressed as a range of values in this table.

Different materials have different requirements. Woods with a dense grain, such as oak or maple, use a jigsaw blade with a higher TPI value than less dense woods such as balsa.

While tooth count is important in helping to determine the quality of a saw blade, it’s not an absolute indicator of performance. Tooth design also plays a role in how well a blade will perform on any given material. Always check the manufacturer’s recommendations for the best results. Want to know more? I wrote another article called: What is a Jigsaw?

Final Thoughts

I hope this article has been able to give you additional insight into the world of jigsaw blades, as well as help you select the best blade for your needs. My main takeaway is that there’s a huge variety in the market, and each one requires its own set of specifications to meet the need of its respective niche. For example, a blade meant for fine joinery might not be ideal for cutting plywood. With this reality in mind, consider what types of projects you work on the most, and choose the blades accordingly.

Did you enjoy this post? If so, you might enjoy visiting my Pinterest profile. It contains pins about Woodworking, Tools, DIY & Crafting, Projects, Hardware, and similar topics.

Related Posts:

Can I Buy Exotic Woods Online?

Can An Electric Drill Be Used As A Screwdriver?

Can An Electric Drill Be Used As A Sander?

How To Make A Hole In Wood Without A Drill