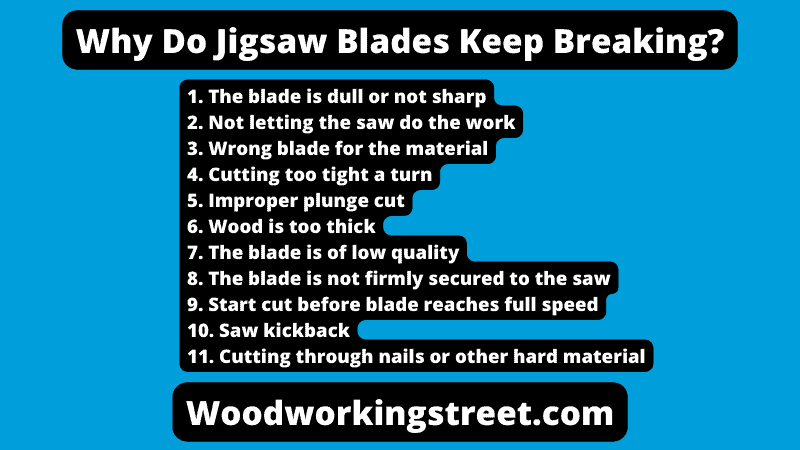

What’s the most annoying thing that can happen while using a jigsaw? That’s right, a broken blade. This can be super frustrating when you’re in the middle of a project and have to order new blades. Whether you have been using your jigsaw daily to cut wood or just occasionally on smaller projects, at some point you may experience one or more of these reasons why your jigsaw blades keep breaking:

The blade is dull or not sharp

A dull jigsaw blade just doesn’t have the same cutting power as a sharp one. It takes much more force to cut through material with a dull blade than one that’s sharp. Because of the increased pressure required to get the blade through the material, the blade heats up very quickly and is prone to breaking.

It’s easy for blades to break when cutting thick materials or large panels such as plywood. Dull blades can bind to the material being cut, which may cause the saw to kick back and hit you, possibly injuring your hands or face. It’s important to keep your blades sharp for safety.

A sharp blade (which has a cutting edge that’s been ground or honed) slices into the wood fibers instead of “plowing” through them like a dull blade does, which reduces friction and heat build-up during the cut, extending the life of the blade.

A dull jigsaw blade breaks. Period. It doesn’t matter if you’re a hobbyist or a professional woodworker—a dull blade is a disaster waiting to happen and should be replaced immediately.

Not letting the saw do the work

The saw is doing the cutting, not you. You only guide it along. Let the saw do the work. Do not push or force it to cut faster than the blade can naturally move through the wood.

Using the saw to cut slowly and carefully will do a better job. You’ll achieve a straighter cut, and the odds of breaking expensive jigsaw blades will be greatly reduced with this method. When you apply pressure to the saw, heat builds up on the blade. This heat may cause the blade to break or become more likely to break under the stress of cutting.

Remember not to force your jigsaw blade through the wood. Pushing hard on your jigsaw may also make it more difficult to get a straight cut. Slow down and take your time when using your jigsaw so that you’re less likely to break the blade.

Wrong blade for the material

Selecting the correct jigsaw blades for the appropriate project is important to ensure maximum performance and longevity of a blade, as well as safety.

To ensure the best results and longest lifespan, it is important to know what types of materials each blade can cut. Blades are often identified by the type of material they are best suited for. Some blades are made specifically to cut wood while others are made to cut metal.

Some blades have a universal design that can be used on wood, metal, and even plastic. Using a blade that was not designed for the material being cut can result in the blade breaking.

When picking the right blade for your jigsaw it is important to know what type of material you are cutting. If you are not sure what types of materials are best suited for your jigsaw, you should always check with the manufacturer. Not only will they have the most up-to-date recommendations but they can also recommend blades that will help make your job easier.

Cutting too tight a turn

One of the most common causes of broken blades is making too sharp a turn with the blade. This can happen when you’re cutting an inside corner.

Use a narrow jigsaw blade if you’re cutting out small, intricate shapes. The narrow blades are able to cut sharper turns because there is less binding of the blade. Narrow blades are also easier to control, especially when making fine cuts or doing detailed work.

Always wear safety glasses when working with any power tool. Keep your hands out of the line of cut at all times. Cut slowly to avoid excess strain on the blade. Also, never cut faster than you can see. This will help to prevent injury.

Improper plunge cut

These cuts can be made safely with a jigsaw, but they can also cause the blade to snap if you’re not careful.

To make a plunge cut, hold your saw at a slight angle from the front base of the piece you are cutting. Then tilt it down slightly so that the blade cuts down into the wood. The important thing when doing this kind of cut is to have a sharp tip on your saw blade.

This type of cut allows you to cut from the interior of any given piece, whereas other types of cuts don’t allow this. This is why it’s so helpful for certain tasks – such as cutting out openings in paneling for outlet boxes, for example.

A jigsaw blade can break during a plunge cut. The force of the plunge at the bottom of the cut can sometimes cause the blade to snap, sending bits of metal flying toward your face.

Stay aware of how much pressure you’re putting on the blade. The more pressure you put on it, the more likely it is that the blade will break. Always wear safety goggles when operating a jigsaw.

Wood is too thick

A jigsaw blade can be broken during cutting if it becomes bound as it travels up and down. This can happen when cutting wood that is too thick or too hard for the blade.

A blade can also bend and cause a cut that is not accurate. The following are guidelines for using a jigsaw safely:

- Use blades specifically made for the tool with its speed range.

- Do not use blades that are bent, cracked, or have nicks in them. Replace them.

- Do not use blades longer than the maximum length specified by the manufacturer. If you must trim a long workpiece, make several cuts rather than extending the blade.

- Keep blades sharp by frequently changing them as they become dull. Dull blades cause excessive friction, which heats up the blade.

The cut can also be inaccurate if the teeth get damaged, which will cause the blade to eventually break. If this happens, consider replacing the blade with one of similar size and shape intended for your brand of saw, or take it to a local hardware store or home improvement center to see if it can be sharpened or repaired.

Jigsaws are a great tool for cutting curves, but if you attempt to use one to cut through a board that is too thick, you run the risk of breaking the blade. This is because jigsaw blades are designed to cut wood only up to a certain thickness. If you need to cut wood that is thicker than the maximum thickness specified by the manufacturer, you will need to use another type of saw.

The blade is of low quality

Jigsaw blades can break, especially if they’re not of the best quality. When shopping for jigsaw blades, look for a name brand. These blades aren’t cheap, but they will last longer than the bargain brands.

There are various ways to classify a saw blade, but one factor is the cutting teeth per inch (TPI). The higher the TPI, the finer the cut. Blades with a high TPI are also more expensive. I wrote another article about the TPI of a Jigsaw blade.

There are a lot of factors that go into choosing a blade for your Jigsaw. They are all about quality, performance, and durability. Three materials commonly used in Jigsaw blades are:

High-Carbon Steel: These blades are typically the most affordable out of all the other blades on the market. However, they do not last as long as most of the others and will dull more quickly.

High-Speed Steel: These blades are often used with harder materials such as metal. However, they are more brittle and less flexible than High-Carbon Steel blades.

Bi-Metal: These blades consist of a mixture of High-Carbon Steel and High-Speed Steel. This design allows the blade to last longer than high carbon steel or High-Speed steel alone.

Jigsaw blades are a necessity when you’re doing any kind of woodworking project. However, they’re not all created equally. The low-quality blades can snap or break much too easily, leaving you with a jagged edge on your project.

The blade is not firmly secured to the saw

The first thing you should check when your jigsaw blade breaks is whether or not the blade is loose. Jigsaws can vibrate and shake while cutting, so if a blade is not securely fastened to the saw, it has the potential to vibrate and shake off of the clamp that is holding it in place. If this happens, the blade could strike anything in its path as it flies off of the saw. If your jigsaw blade snaps and hits someone with a flying piece of metal or wood, it could cause serious injury.

Jigsaws come in different types with different mounting systems. The older style saws use U-shank blades which need to be secured with a setscrew and Allen wrench. The newer ones use T-shank blades which don’t require any tools and are much easier to attach.

You can check if the blade fits properly into the saw and whether it moves freely or not. If it does not move freely, check if there is any rust or corrosion as this might hamper smooth movement. If you find any rust or corrosion, immediately remove it (before using the saw).

There are several reasons that you may be having trouble keeping your jigsaw blade secure. The most common reason is that the blade may have been installed incorrectly. However, there are other reasons why your jigsaw blade may be loose. Here are three of them:

Scratches or chips on the base: If your blades show signs of damage, you may need to inspect them to make sure that they fit into the jigsaw clamp properly. To ensure optimal performance, make sure to change your blade regularly.

Blade not sitting correctly: This can also cause the blade to be loose. You should check this regularly while using your jigsaw by ensuring that the blade is sitting flat in its seating. If it’s sitting at an angle or the base of the blade is not resting evenly on the seat, it could snap or break.

Damage: If there is any damage to your jigsaw’s base or area where the blade sits, you could find that the blade becomes loose and eventually breaks from being repeatedly put on and removed from this area. Often, damaged areas can be repaired with epoxy glue.

Jigsaws are an indispensable tool for cutting wood. But a loose blade can cause accidents and is also dangerous to use.

Start cut before blade reaches full speed

When cutting with a jigsaw, do not start before the blade reaches full speed. It can damage your saw and lead to kickback or broken blades.

If you begin the cut before the saw has reached full speed, it can cause the blade to break, especially if it’s blunt or if you’re trying to cut through something hard.

It is very easy to accidentally break a jigsaw blade when the saw is first turned on. The blade can try to “jump” out of the cut, resulting in a snapped blade. To avoid this problem, allow the saw to run for a while before starting the cut.

Jigsaw blades are very strong and durable, however, when the saw isn’t running at full speed, they will break more easily. This is due to the fact that the saw is not able to cut through whatever you are cutting as smoothly as possible because the saw isn’t running fast enough when it begins to cut.

Saw kickback

A kickback occurs when the jigsaw gets stuck in the wood and begins to jump, which can cause the blade to break. When kickback happens, a piece of the blade is often flung back at the user, hitting them in the face or hands.

Jigsaws are powerful tools capable of making quick work of almost any cutting task. If used properly, they can be safe and effective tools that provide years of service. However, if used improperly, they can cause damage to both materials and users.

When it comes to picking out and using a jigsaw, proper safety precautions must be taken to ensure it’s a tool rather than a weapon. The best ways to avoid kickback with a jigsaw are to slowly feed the saw through the material, use an appropriate blade, and clamp down your work.

Another possible cause of Jigsaw kickback is trying to cut a material that is thicker than the depth of the saw’s blade. Always make sure that your materials are securely fastened to the surface that they are being cut on so they don’t move around while you are cutting them. Always keep pressure on your material while you’re cutting, but be careful not to put so much pressure on it that you press it into your work surface or cause it to bend or bow.

Cutting through nails or other hard material

Be very careful when using the jigsaw around objects like nails or screws. Don’t force your way into them and take it slowly if you encounter resistance from the blade against something hard.

If you are cutting through nails with the jigsaw, then there is the risk that you will damage your jigsaw blade in doing so. If you do cut through nails with the Jigsaw and the blade breaks, you may still be able to use the Jigsaw by removing the damaged blade.

Fortunately, there are ways to prevent this from happening and still be able to get your job done effectively. The first thing you should do is ensure that your jigsaw blade is sharp enough to begin with. This will help to prevent any bending and make it easier to cut through materials like nails.

Finally, if possible, it’s a good idea to clamp down on the object you are trying to cut so that it remains still and does not move.

For more information, see another article I wrote called: What is a Jigsaw?

Conclusion

No one likes to break a blade. But, when it happens, you need to know why it happened, and how you can avoid it in the future. While jigsaw blades are quite strong and suitable for a variety of cutting applications, there are some instances where they can fail — and how you deal with those situations can help keep your machines running smoothly between blade changes.

These top eleven reasons should at least help you figure out where to start if your blade keeps breaking. If you’re not sure, check each reason and see if it describes one of the situations you faced when breaking a blade. If so, take the appropriate steps to avoid these situations in the future. Be extra careful when working with blades made of cheap materials as they are much more likely to break under pressure.

Did you enjoy reading this post? If so, you might like to visit my Pinterest profile. It contains pins about Woodworking, DIY & Crafts, Tools, and related items.